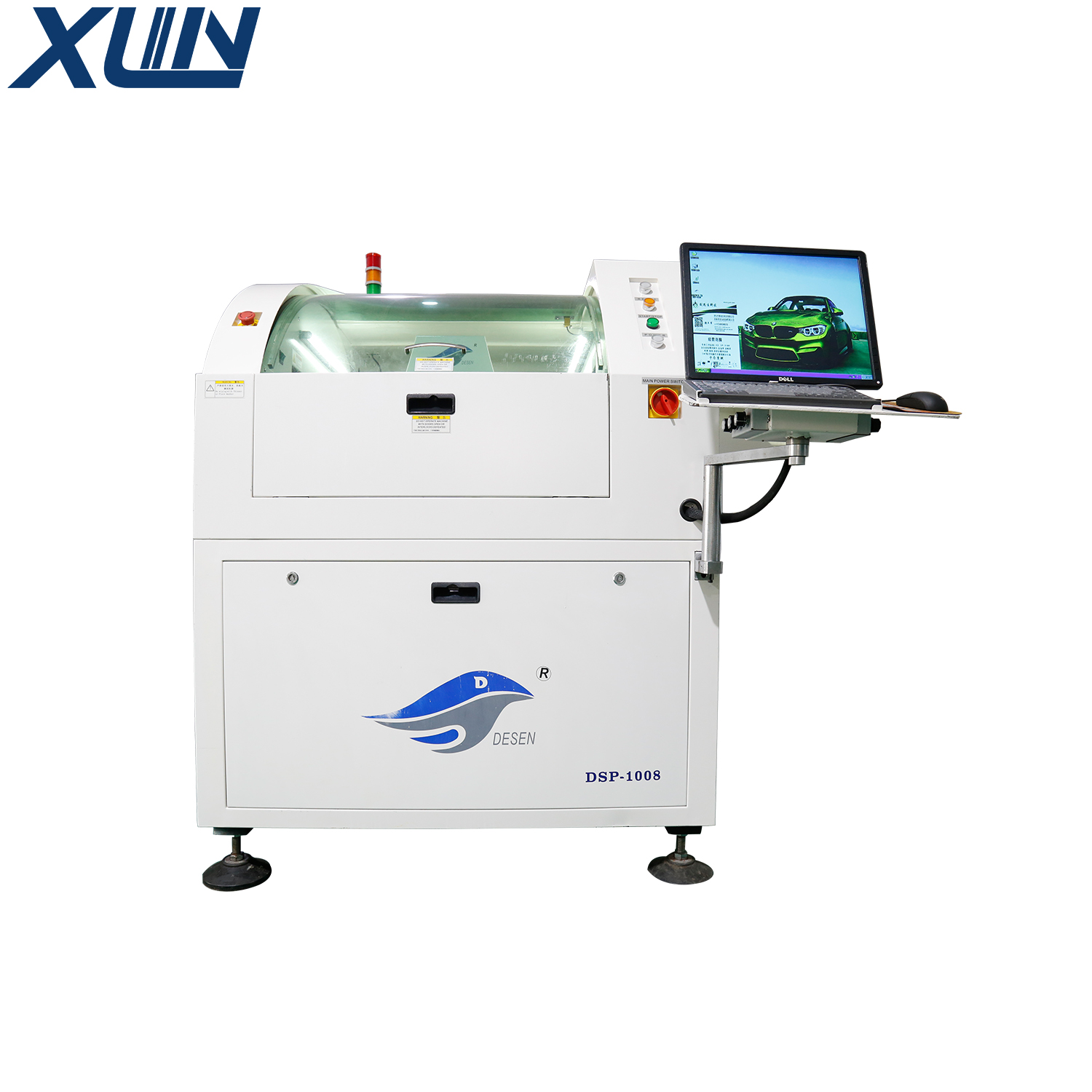

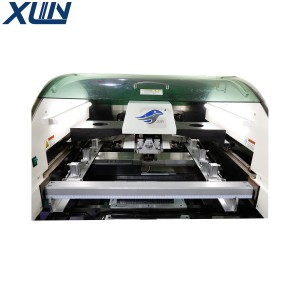

High Speed Full-Automatic PCB SMT Solder Paste Tshuab Luam Ntawv PCB SMT Stencil tshuab luam ntawv

Niaj hnub nimno solder paste tshuab luam ntawv feem ntau yog tsim los ntawm cov phaj thauj khoom, ntxiv cov tshuaj txhuam hniav, embossing, Circuit Court board kis tau tus mob thiab lwm yam. Nws txoj hauv kev ua haujlwm yog: ua ntej txhim kho lub rooj tsav xwm hauv Circuit Court kom luam tawm ntawm lub tshuab luam ntawv qhov chaw, thiab tom qab ntawd sab laug thiab sab xis scrapers ntawm lub tshuab luam ntawv xau cov kua nplaum los yog cov kua nplaum liab rau cov ntaub qhwv los ntawm cov hlau mesh. Lub PCB nrog cov ntawv tsis sib xws yog nkag mus rau lub mounter los ntawm lub rooj sib kis rau kev sib txuas tsis siv neeg.

Cov kauj ruam ua haujlwm ntawm SMT tsis siv neeg tshuab luam ntawv:

1. Tshawb xyuas thiab pib cov cuab yeej ua ntej ua haujlwm raws li cov txheej txheem ua haujlwm;

2. Muab lub PCB (PCB deformation tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm kev tsim khoom, thiab ib lub phaj txhawb nqa yuav tsum tau ntxiv) rau ntawm qhov chaw thau khoom;

3. Muab lub vijtsam tso rau ntawm lub tshuab luam ntawv raws li kev taw qhia los ntawm lub vijtsam xub;

4. Xaiv cov kev pabcuam luam ntawv raws li cov khoom tsim, nkag mus rau * * hom rau kev tshuaj ntsuam calibration, thiab debug lub xeev luam ntawv;

5. Kev hloov luam ntawv: kho cov luam ntawv ceev, siab thiab lub kaum ntse ntse kom ua kom cov nyiaj ntawm cov ntawv luam tawm ntawm PCB ncoo tsis tu ncua;

6. Thawj tsab xov xwm yuav tsum tau lees paub los ntawm tus kws tshaj lij thiab kev tsim khoom loj yuav tsum tau ua tom qab nws tsim nyog;

7. Txhua 30 daim ntawv luam tawm yuav tsum raug tshuaj xyuas los ntawm tus neeg soj ntsuam thiab xa mus rau lub mounter tom qab dhau qhov kev tshuaj ntsuam xyuas;

8. Tom qab kev ua haujlwm, tshem tawm lub npov npo thiab ntxuav nws, kaw nws raws li cov txheej txheem ua haujlwm, thiab ntxuav lub rooj ua haujlwm.

Yuav tsum muaj rau SMT tshuab luam ntawv tsis siv neeg:

1. Hnav cov hnab looj tes roj hmab lossis cov hnab looj tes pov tseg thaum ua haujlwm ntawm cov tshuaj txhuam hniav. Yog hais tias cov tshuaj txhuam hniav yog ua raws li daim tawv nqaij, tam sim ntawd ntxuav nws nrog cawv thiab tshuaj ntxuav tes, thiab ntxuav nws nrog dej ntau;

2. Cov tshuaj txhuam hniav uas tseem tshuav, siv cov tshuaj ntxuav cov ntawv so thiab cov hnab looj tes pov tseg tom qab ua haujlwm yuav tsum raug kho raws li cov kev cai ntawm ib puag ncig;

3. Ntxuav cov cuab yeej, cov cuab yeej thiab cov cuab yeej ua ntej siv, tshwj xeeb tshaj yog them nyiaj tshwj xeeb rau kev tiv thaiv ib puag ncig ntawm qhov chaw ua ntej ua cov khoom tsis muaj hlau lead.

PCB Parameters

Qauv: DSP-1008

Qhov siab tshaj plaws board loj (X x Y) 400mm × 340mm

Yam tsawg kawg nkaus board loj 50mm × 50mm

PCB thickness 0.4-5 hli

Warpage ≤1% Diagonal

Qhov siab tshaj plaws board hnyav 0-3kg

Board margin qhov sib txawv 20mm

Hloov ceev 1500mm / s (Max)

Hloov qhov siab ntawm hauv av 900 ± 40mm

Hloov orbit kev taw qhia sab laug-txoj cai, sab xis-sab laug, sab laug-sab laug, sab xis-txoj cai

Hloov hom Ib theem orbit

PCB damping method Programmable saj zawg zog sab siab + Adaptive PCB board thickness + Ntug xauv lub hauv paus clamp (Yeem: 1. Multipoint ib nrab nqus tsev vacuum ntawm hauv qab; 2. Ntug xauv thiab substrate clamping)

Txhawb txoj kev Sib Nqus thimble, Sib npaug siab thaiv, thiab lwm yam.(Yeem: 1.Nqus Chamber; 2.Tshwj xeeb workpiece fixture)

Performance Parameters

Repetition precision ntawm cov duab calibration ± 10.0μm @ 6 σ, Cpk ≥ 2.0

Repetition precision ntawm printing ± 20.0μm @ 6 σ, Cpk ≥ 2.0

Lub sijhawm voj voog<7s (Tsis suav luam tawm thiab tu)

Cov khoom hloov pauv<5 feeb<br /> Duab Parameters

Field of view 8mm x 6mm

Platform hloov ntau yam X: ± 5.0mm, Y: ± 7.0mm, θ: ± 2.0 °

Benchmark point type Standard shape benchmark point (SMEMA standard), solder ncoo / qhib

Lub koob yees duab system Independent lub koob yees duab, upwards/downwards imaging vision system

Printing Parameters

Printing taub hau Floating ntse tshuab luam ntawv taub hau (ob ywj siab ncaj qha kev cob cog rua motors)

Template ncej loj 470mm x 370mm ~ 737 mm x 737 mm

Qhov siab tshaj plaws luam ntawv cheeb tsam (X x Y) 450mm x 350mm

Squeegee hom Steel scraper / Glue scraper (Angel 45 ° / 50 ° / 60 ° txuam cov txheej txheem luam ntawv)

Squeegee ntev 300mm (yeem nrog ntev ntawm 200mm-500mm)

Squeegee qhov siab 65 ± 1mm

Squeegee thickness 0.25mm Pob zeb diamond zoo li carbon txheej

Printing hom Ib leeg los yog ob chav scraper luam ntawv

Demoulding ntev 0.02 hli - 12 hli

Printing ceev 0 ~ 200 mm / s

Printing siab 0.5kg - 10Kg

Printing stroke ± 200 hli (ntawm qhov chaw)

Kev huv huv

Kev tu hom 1. Kev tu lub cev; 2. Hom qhuav, ntub thiab nqus tsev

Ntev ntawm kev tu thiab so lub rooj tsavxwm 380mm (yeem nrog 300mm, 450mm, 500mm)

Khoom siv

Lub zog xav tau 220 ± 10%, 60 / 60HZ-1 ¢

Compressed cua xav tau 4.5 ~ 6Kg / cm2

Sab nraud qhov ntev 1114mm (L) * 1360mm (W) * 1500mm (H)